Japanese architecture and building codes have evolved over time to defend against the ever-present threat of earthquakes. Still, no amount of calculations, small-scale physical models or virtual computer modeling can substitute for real world testing. Hence the E-Defense (short for Earth Defense) complex, which houses Japan’s full-scale earthquake simulator. This giant device was designed and built in the wake of a particularly devastating natural disaster.

The 6.8-magnitude earthquake that struck Kobe in 1995 was a wake-up call for the Japanese government. “In total,” writes architect Alastair Townsend, “around 150,000 properties were ruined by the earthquake and ensuing fires, leaving 300,000 homeless. 6,300 people lost their lives.” Predictably, many older buildings that were insufficiently braced for lateral loads (shaking side to side) were damaged or destroyed. But newer buildings also suffered more in the quake than expected.

Townsend, who spent years running an architectural practice in Japan, explains that “these surprising failures exposed an unsettling truth: calculations alone could not fully predict the complex movements that bring buildings crashing down in a major seismic event.” Computer models help but are necessarily abstract. Miniature physical models can distort full-scale forces. But “to remove all doubt, one would have to build a full-scale model and subject it a full-force earthquake simulation to confirm its seismic strength and expose any critical points of failure.” It may sound like an improbable solution, but the Japanese government went ahead and built just such a simulation system.

Following the disaster in Kobe, Japan’s National Institute for Earth Science and Disaster Prevention (NIED) began designing a huge “shake table” that could emulate magnitude 7 quakes. Formally known as the 3D Full-Scale Earthquake Testing Facility, this project was completed for E-Defense in 2005. The machine “is an engineering marvel in its own right,” as Townsend describes it, “with awesome destructiveness comparable to the robotic mecha giants, who fight to safeguard Japanese cities from annihilation in popular manga and anime series.”

Inside the project’s Experiment Building, whole multistory buildings are placed on a platform that moves back and forth as well as vertically, simulating complex seismic effects in all three dimensions. The results are observed externally but also measured internally using an array of cameras and sensors placed inside the shaken structures.

“The shake table is powered by hydraulics,” explains Townsend, “like the tricked-out suspensions that jack lowrider cars up and down. In a neighboring shed, four immense 4,300-horsepower gas engines power the hydraulic pumps that pressurize the system.” Special joints and pistons allow the platform to move in three dimensions.

The E-Defense system pushes some test buildings to their breaking point and demonstrates the efficacy of retrofits in others. The experiments go beyond the shells of structures, too — inside, rooms can be staged with full-size furniture, fixtures and human figures. Lessons learned from these lifelike simulations can be used to future-proof new architecture against likely disasters.

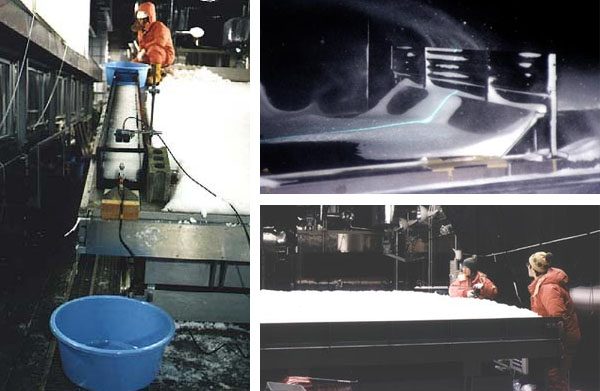

NIED also features a smaller shake table in addition to a rainfall simulator and a cyrospheric environment simulator. The last of these is designed to study snow disasters (including avalanches, often caused by quakes) using a snow-making machine and wind tunnel system.

In Japan, tremors are a fact of everyday life and residents have learned to expect earthquakes. The real estate industry even markets some homes using videos (like the one above) of their performance during simulated disasters. Per Townsend: “the frequent sensation of rocking and jolting underscores that buildings are not static, but behave like kinetic mechanisms …. Witnessing buildings move on this scale defies our tacit perception that they are solid, brittle, and unyielding objects.”

This familiarity with quakes has long informed historic building traditions in Japan, leading to innovations like interlocking wood joints (using no screws or glue). Coupled with a practice of setting wooden buildings loosely on foundations (letting them vibrate freely), these loose joints allow movement and in turn help absorb shocks.

The persistence of tectonic perils also informs construction and demolition practices around newer buildings made of concrete, glass and steel. Techniques have been developed, for instance, to carefully deconstruct out-of-date buildings after just a few decades while minimizing pollution, waste, energy and expense in the process.

A history of natural disasters has also led to a long tradition of marking safe building areas with tsunami stones. These large monuments indicate high-water points from historic tsunamis. Many of them were placed centuries ago and some continue to serve as warnings today.

Meanwhile, other modeling centers similar to E-Defense have been built in other places, but this system remains the largest of its kind. Engineers from around the world bring their designs to be shaken to (or past) their breaking points in this unique experimental complex.

Leave a Comment

Share