There’s something about rebar that fascinates me. If nothing else because there are very few things that invoke a fear of being skewered. My preoccupation with metal reinforcement bars dovetails nicely with a structure in San Francisco I’ve kind of become obsessed with — a tiny bridge on the eastern edge of Golden Gate Park called the Alvord Lake Bridge.

Ernest Ransome, the father of modern rebar, constructed the bridge in 1889. Today, it is a dumpy, cracked, and neglected structure. The inside is a surreal tunnel of phony stalactites.

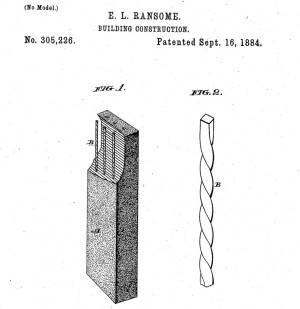

But the Alvord Lake Bridge is, quite literally, the bridge to the modern world. It is one of the oldest reinforced concrete structures still standing. The twisted iron bars embedded in the bridge served as the model for all the rebar containing structures that followed. It is the ancestor to an endless number of reinforced concrete buildings, bridges, tunnels, viaducts, and foundations. Ransome’s major innovation in rebar was to twist the square bar so that it bonded to the concrete better.

Concrete has incredible compression strength, but it does not have much tensile strength. So if you want concrete to span any significant distance, you need to embed metal reinforcement.

There are plenty of candidates for the most overlooked, most invisible part of the built world, but reinforced concrete has a good claim to being the most invisible of all. Because if it’s made right, you never see the steel skeleton underneath all the concrete structures that you work in, drive over, and walk under.

The problem with steel reinforcement is that it rusts. When the steel begins to rust, the bond with the surrounding concrete is broken. The rusted metal also swells and breaks the concrete apart. Because of this, most of the reinforced concrete structures that are constantly exposed to the elements (like our highway system) were only designed to last 50 years. More advanced concrete mixtures and epoxy coated rebar increase the longevity, but without regular maintenance, entropy eventually wins out.

Ernest Ransome left San Francisco soon after he completed the Alvord Lake Bridge. In his book “Reinforced Concrete Buildings” published in 1912, you can detect a tinge of bitterness in Ransome’s text as he describes how his twisted rebar was “laughed down” by the Technical Society in California. He left for the east thinking that his revolution of reinforced concrete would have a better chance out there. He left thinking that no one here would fully appreciate his Alvord Lake Bridge, his bridge to the modern world. And looking at it today, I’m sad to say, he was right.

Thanks to CCA Senior Adjunct Professor of Architecture, William Littman (he of the Forgotten Monument) for first telling me about the Alvord Lake Bridge and showing me around. I spoke with Robert Courland, author of Concrete Planet: The Strange and Fascinating Story of the World’s Most Common Man-Made Material (a great book!), and Bob Risser of the Concrete Reinforcing Steel Institute (a great person to talk to!).

A very special thanks to Bay Area architect and photographer Eddy Joaquim for shooting the bridge for the show. Eddy and his wife, Maile, are also the hosts of the truly excellent Big Tiny Salon, where I first talked about this story in May 2012.

Check the timed comments on the Soundcloud file for a list of the music used in this episode.

Comments (11)

Share

http://www.apnewsarchive.com/1990/Boy-Impaled-By-Rod-Improving-Hospital-Official-Says/id-2690799b8a220fcf373c48b29232cdbf

The Wilhelm Scream in the intro was a stroke of genius.

Love the music at 2:40…tip of the hat to Upstream Color?

Hi thanks to share this valuable information. It makes me aware about rebar advantages and disadvantages. Really nice blog

50 years is not very long. Almost a joke by Roman standards. Surely we can do better.

So why aren’t we using Cor-Ten steel (aka weathering steel) in rebar?

I had to rewind twice to make sure I heard it right, or didn’t dream it, as nobody else—listener or broadcaster—apparently caught it. A reinforced concrete rowboat??!??!? What’s up with that? If not a full episode, might you catch us up on that with a blog post? Enquiring minds (at least this one) want to know more about that concrete rowboat.

I enjoyed hearing this on KALW this morning, and finding this blog afterwards. I’ll check it out as a possible place to scan in 3D since it’s close by.

Some verifiable facts about reinforced concrete.

Only 5-10 percent of the water in concrete goes into the chemical change that turns concrete hard. The rest of the water, about 90 percent, is called “placement water” and is only there to help concrete pour into place.

It takes many decades for this water to leave the concrete, in which time it’s replenished by rain.

Concrete does not “Dry”.

All iron rebar in concrete rusts. The containment of concrete around the rebar must be strong enough to contain the pressure created by the expansion of the iron in the rust process, and when the pressure gets high enough the rusting stops.

If the concrete around the rebar is not thick enough or strong enough you get spalling, which allows water deeper into the concrete.

See”https://www.google.com/search?q=%22Concrete+spalling%22&es_sm=122&tbm=isch&tbo=u&source=univ&sa=X&ei=cEFBVLj0FsWwogSJjoGYCA&ved=0CB8QsAQ&biw=1920&bih=993″

COncrete must by an inch and a half to two inched thick to have the strength to stop the expanding rust. When you see spalling you will usually see that the rebar is too close to the surface.

Mile and miles of Florida causways were rebuilt with epoxy coated rebar, but it was discovered that small cracks or damage to the epoxy created essentially a battery and corrosion was accelerated.

“Concrete Construction.Net”

“Here’s what happens in the bridge concrete. When it is new, the very alkaline environment (high pH) in concrete creates a “passivating” layer around the steel reinforcing bars that prevents them from corroding. At the very high pH of the concrete, the steel cannot corrode or rust. Over time, chloride from deicing salts and carbonation from atmospheric CO2 can penetrate the concrete and destroy the passivating layer. When water and oxygen also get to the reinforcement, the steel begins to corrode or oxidize. The iron in the steel reacts with the water and is oxidized to iron oxide (rust) which has greater volume than the steel. The force of this expansion is greater than the tensile strength of the concrete and so it must crack.”

Fascinating topic.

Thanks for the report on Alvord Lake Bridge.

Craig

I have been giving Haight Ashbury walking tours since 1992 and always mention the Alvord Lake Bridge. It is right at the end of Haight St.

It survived both the 1906 and 1989 earthquakes quite well. Kezar Drive, the road over it, connects 2 of San Francisco’s major east-west thoroughfares, and it is not an exaggeration to say that millions of of cars have crossed it since it was built.

Are you saying the “phony stalactites” were deliberately molded into the bridge?